Aluminum composite cladding has become a go-to solution for architects and engineers seeking a balance between aesthetics, performance, and sustainability in modern building design. This innovative material, composed of two thin aluminum sheets bonded to a lightweight polyethylene core, offers a range of advantages that make it particularly suitable for both commercial and residential structures. From energy efficiency to design flexibility, the benefits of aluminum composite cladding are transforming the way buildings are conceived and constructed.

One of the most compelling reasons to choose aluminum composite cladding is its exceptional durability. The material is resistant to weathering, corrosion, and UV degradation, making it ideal for use in a wide range of climates. In coastal areas, where salt spray and humidity can wreak havoc on traditional building materials, aluminum composite cladding maintains its structural integrity and visual appeal for years. Its resilience also translates into lower maintenance costs over the building’s lifecycle.

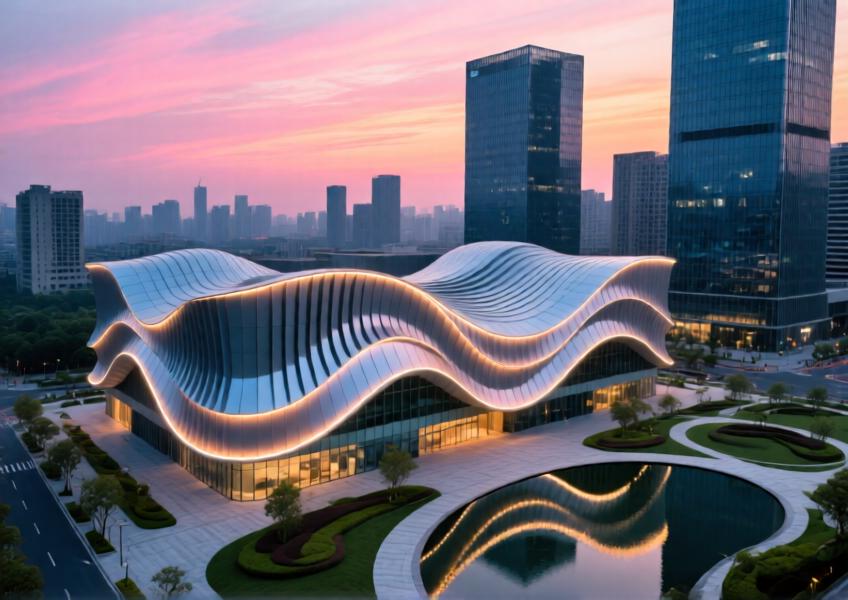

Aesthetic versatility is another major advantage. Available in a wide array of colors, finishes, and textures, aluminum composite cladding allows architects to achieve bold, contemporary designs that stand out. Whether it’s a sleek metallic sheen for a high-rise office tower or a matte finish for a modern residential complex, the material can be tailored to meet specific design visions. This adaptability was clearly demonstrated in a recent mixed‑use development in Shanghai, where the cladding was used to create a dynamic, wave‑like façade that has since become a city landmark.

Beyond looks, aluminum composite cladding contributes significantly to thermal performance. When integrated with insulation systems, it helps regulate indoor temperatures by reducing heat transfer through the building envelope. This not only enhances occupant comfort but also lowers energy consumption for heating and cooling—key considerations in the era of green architecture. In fact, buildings incorporating this cladding system often see measurable improvements in their energy efficiency ratings.

Lightweight yet strong, aluminum composite cladding also simplifies construction logistics. Its low weight reduces structural load requirements, enabling more efficient building designs and potentially lowering foundation and support costs. Additionally, the material is easy to fabricate and install, speeding up the construction timeline and reducing labor expenses.

Environmental considerations further enhance its appeal. Aluminum is highly recyclable, and many manufacturers now offer cladding products with a high percentage of post‑consumer recycled content. As the construction industry moves toward more sustainable practices, aluminum composite cladding offers a responsible choice that aligns with green building standards such as LEED and BREEAM.

Finally, the fire‑resistant properties of certain aluminum composite cladding variants make it a safer option for high‑density urban environments. While standard panels contain a polyethylene core, fire‑rated versions substitute this with a mineral‑filled core that meets stringent fire safety regulations. This makes it suitable for use in high‑rise buildings where fire performance is a critical design factor.

In today’s fast‑evolving architectural landscape, aluminum composite cladding stands out as a material that delivers on both form and function. Its combination of strength, adaptability, and sustainability ensures that it will remain a cornerstone of modern building design for years to come.