In the realm of curtain wall engineering and high-end commercial interior design, the choice of materials can define both the aesthetic appeal and structural integrity of a project. Among the most critical components are metal cladding systems, which offer durability, flexibility in design, and a sleek modern finish. As architects and engineers push the boundaries of innovation, selecting the right metal cladding manufacturers becomes essential to achieving both visual impact and functional performance.

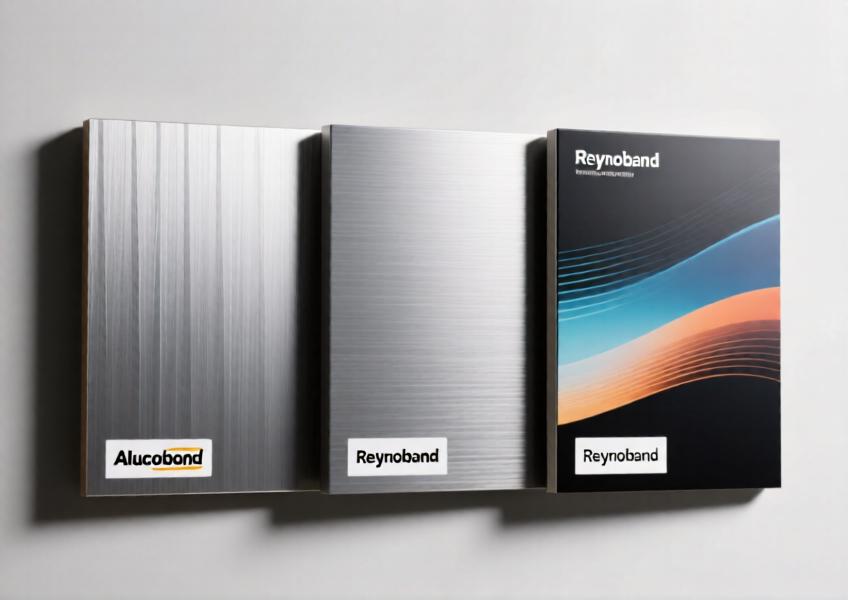

Leading manufacturers have risen to this challenge by offering advanced solutions tailored to the complexities of curtain wall systems and interior architectural features. Companies such as Alucobond, Reynobond, and 3A Composites have established themselves as pioneers in the industry, providing high-quality aluminum composite panels that meet stringent international standards. Their products are engineered to withstand environmental stressors while offering a wide range of finishes, from brushed metal to custom digital prints, enabling architects to realize their boldest visions.

Beyond material excellence, the best metal cladding manufacturers also invest heavily in research and development, ensuring their products align with evolving sustainability goals. Many now offer recyclable materials and low-emission coating technologies, reflecting a growing trend toward eco-conscious building practices in public decoration engineering and luxury residential developments. These innovations not only enhance the environmental footprint of a building but also contribute to certifications such as LEED and BREEAM.

In commercial interiors, where form and function must coexist seamlessly, metal cladding serves as both a structural and decorative element. From feature walls in high-end retail spaces to ceiling systems in corporate lobbies, the precision and adaptability of cladding panels from top-tier manufacturers allow for intricate geometric patterns and seamless integration with lighting and ventilation systems. This level of customization is made possible through advanced fabrication techniques and close collaboration between manufacturers and design teams.

Ultimately, the success of a curtain wall or interior architectural project hinges on the expertise and reliability of the chosen metal cladding manufacturers. As the industry continues to evolve, these manufacturers not only supply materials but also act as strategic partners, offering technical support, performance data, and tailored solutions that elevate the built environment.