Perforated aluminum panels have emerged as a favored material in both modern curtain wall systems and commercial interior design, blending functionality with aesthetic appeal. Their versatility allows architects and designers to push creative boundaries while meeting practical demands such as ventilation, light control, and acoustic performance.

In curtain wall applications, perforated aluminum panels are often used as sun-shading devices or decorative facades. By adjusting the size, shape, and density of the perforations, designers can manipulate how light filters through the building envelope, creating dynamic visual effects that change throughout the day. For instance, a commercial high-rise in Shanghai incorporated custom-patterned perforated aluminum panels to reduce solar heat gain while casting intricate shadow patterns on its glass surfaces, enhancing the building’s visual depth.

Beyond their role in exterior design, perforated aluminum panels are increasingly used in commercial interiors to define spatial zones without obstructing light flow. In a recent luxury shopping mall project in Chengdu, these panels were installed as partition screens between retail spaces and circulation areas. The perforations allowed for a subtle visual connection while maintaining acoustic separation, contributing to a cohesive and breathable atmosphere.

The material advantages of aluminum further bolster its popularity. It is lightweight, corrosion-resistant, and easily recyclable, making it an environmentally responsible choice. Moreover, perforated aluminum panels can be powder-coated in a wide range of colors or finished with metallic effects to match specific design themes. This adaptability has made them a staple in projects ranging from high-end office lobbies to airport terminals and cultural centers.

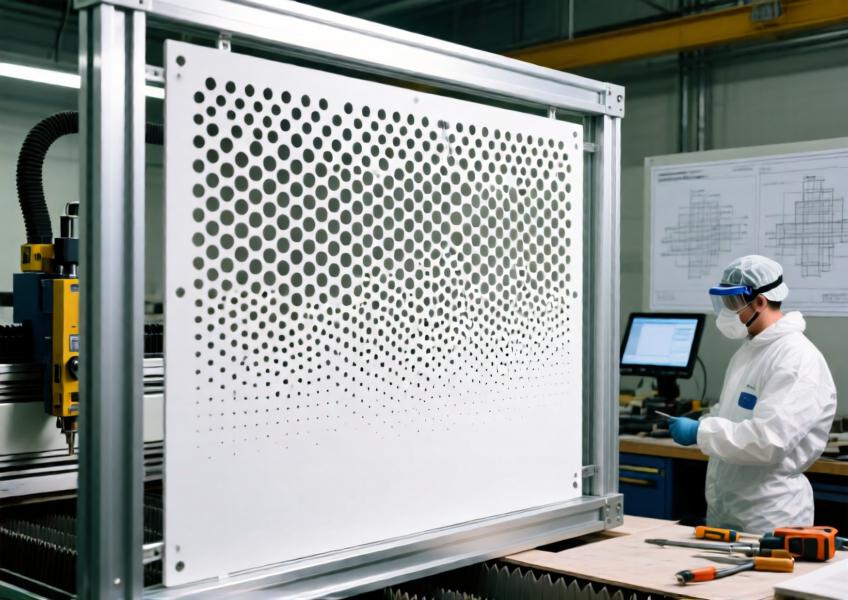

From a technical standpoint, precision in perforation layout is crucial. Designers often collaborate with engineers to ensure that the panel’s perforation pattern aligns with structural, acoustic, and airflow requirements. Digital fabrication techniques such as CNC punching and laser cutting have made it easier to achieve complex geometries and tailor-made designs, enabling architects to translate intricate artistic visions into reality.

Ultimately, perforated aluminum panels represent a harmonious intersection of form and function. Whether used to sculpt sunlight on a building’s façade or to add texture and rhythm within an interior space, they continue to redefine the aesthetics and performance of modern architecture.